Blank Pre Trip Inspection Checklist Template

Before embarking on any journey, especially when operating large vehicles like trucks or buses, ensuring safety is paramount. The Pre Trip Inspection Checklist serves as a vital tool for drivers to assess their vehicles before hitting the road. This checklist typically includes a series of critical components that need to be examined, such as brakes, lights, tires, and fluid levels. By systematically reviewing these elements, drivers can identify potential issues that could lead to accidents or breakdowns. Furthermore, the checklist often prompts the driver to check safety equipment, such as fire extinguishers and first aid kits, ensuring that they are prepared for emergencies. Completing this inspection not only promotes safety for the driver and passengers but also helps in maintaining the vehicle's longevity. In addition, many regulations require drivers to document this inspection, making the checklist an essential part of compliance with transportation laws. Overall, the Pre Trip Inspection Checklist is a fundamental practice that underscores the importance of diligence and responsibility in vehicle operation.

Document Example

Class A CDL

®

®

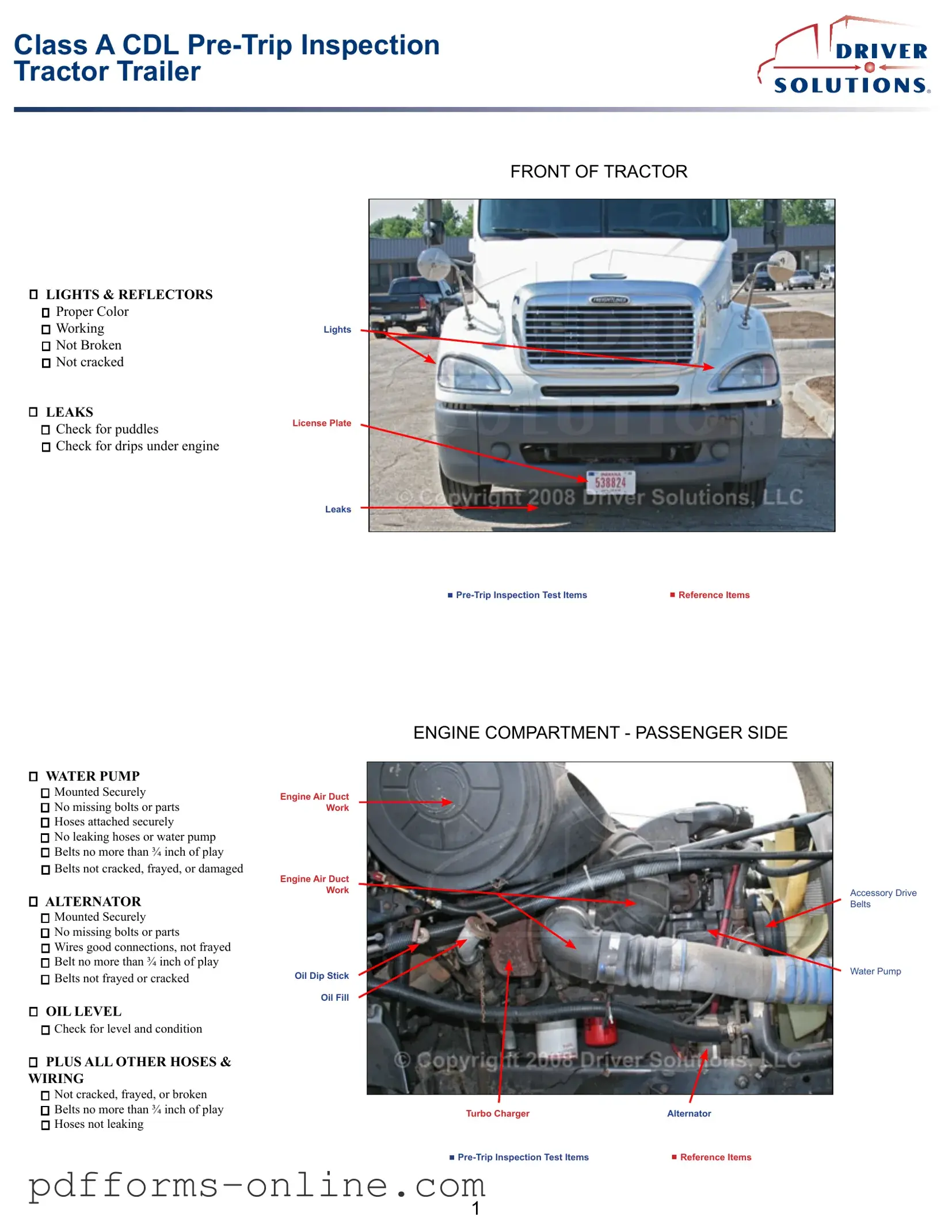

FRONT OF TRACTOR

LIGHTS & REFLECTORS o Proper Color

o Working

o Not Broken o Not cracked

LEAKS

o Check for puddles

o Check for drips under engine

Lights

License Plate

Leaks

Reference Items |

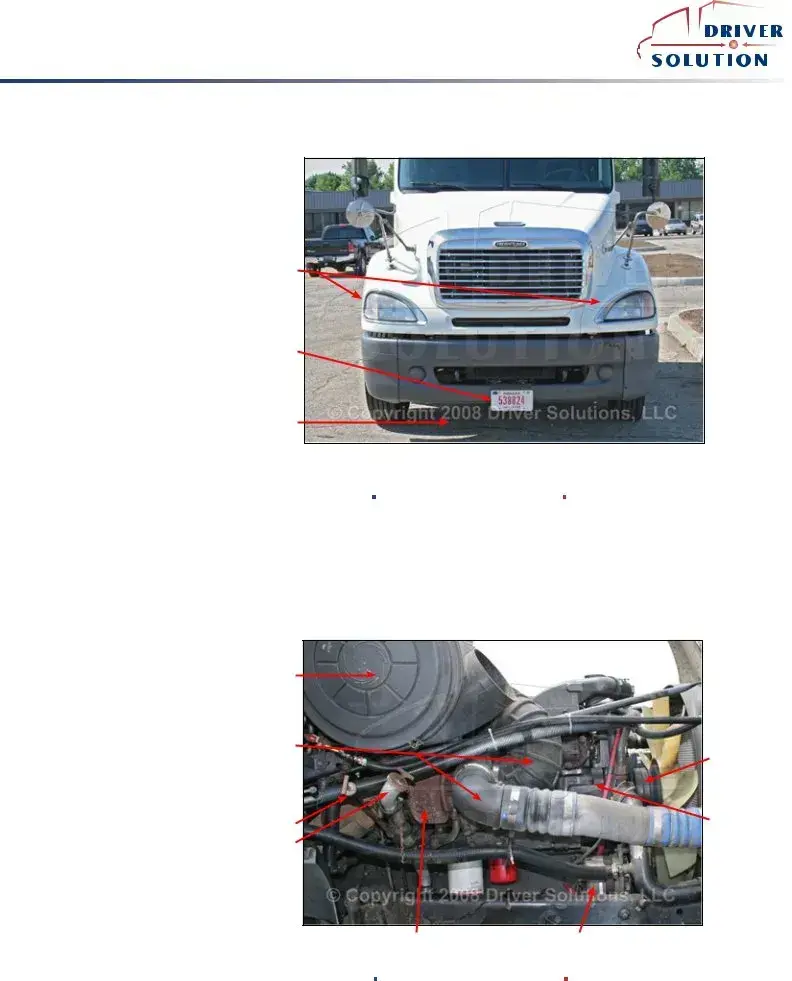

ENGINE COMPARTMENT - PASSENGER SIDE

WATER PUMP o Mounted Securely

o No missing bolts or parts o Hoses attached securely

o No leaking hoses or water pump o Belts no more than ¾ inch of play

o Belts not cracked, frayed, or damaged

ALTERNATOR

o Mounted Securely

o No missing bolts or parts

oWires good connections, not frayed

oBelt no more than ¾ inch of play

oBelts not frayed or cracked

OIL LEVEL

oCheck for level and condition

PLUS ALL OTHER HOSES & WIRING

oNot cracked, frayed, or broken

oBelts no more than ¾ inch of play o Hoses not leaking

Engine Air Duct Work

Engine Air Duct Work

Oil Dip Stick

Oil Fill

|

Accessory Drive |

|

Belts |

|

Water Pump |

Turbo Charger |

Alternator |

Reference Items |

1

Class A CDL

®

®

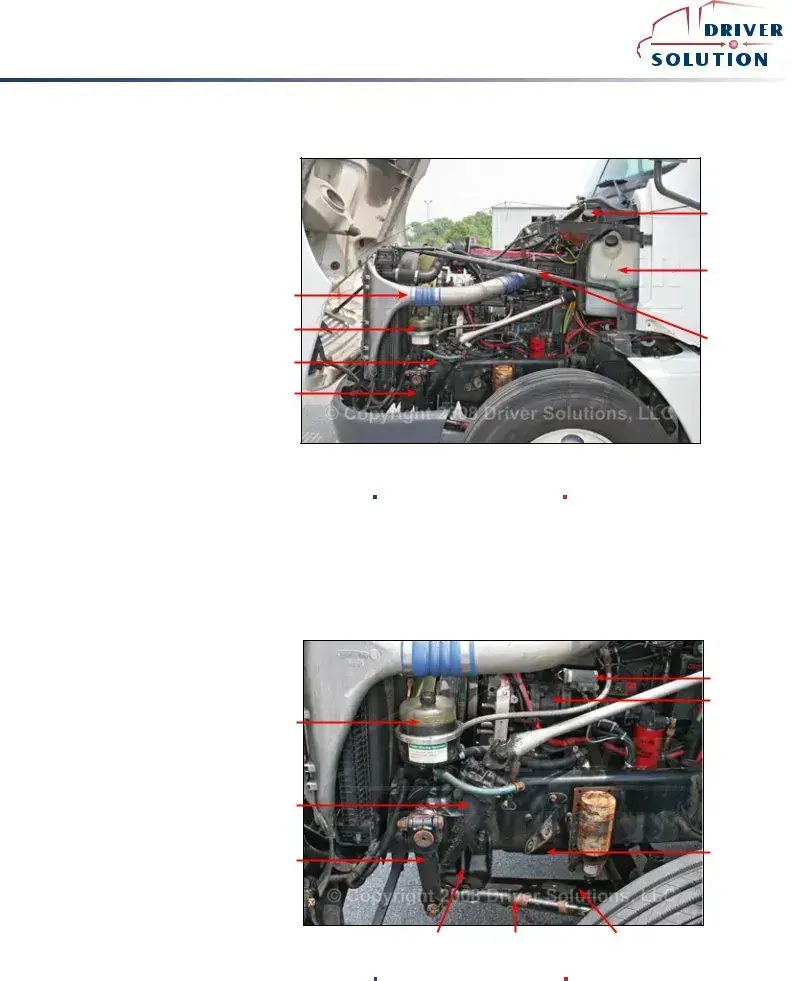

ENGINE COMPARTMENT - DRIVER SIDE

COOLANT

oCheck for level and condition

oHoses attached and not leaking

POWER STEERING RESERVOIR

oMounted properly

oHoses attached and not leaking

oCheck for level and condition

AIR COMPRESSOR

oMounted Securely

oNo missing bolts or parts

oNo air leaks at lines

oCheck if gear or belt driven

oBelt no more than ¾ inch of play

oBelts not cracked or frayed

STEERING GEAR BOX

oMounted properly

oNo missing parts, nuts or bolts o Lines and hoses not leaking or broken

|

Engine Coolant |

|

Reservoir |

|

Windsheild |

|

Washer Fluid |

|

Reservoir |

Engine Air Duct |

|

Work |

|

Power Steering |

|

Reservoir |

Radiator Brace |

|

|

Steering Gear |

|

Box |

|

Pitman Arm |

|

Reference Items |

POWER STEERING RESERVOIR |

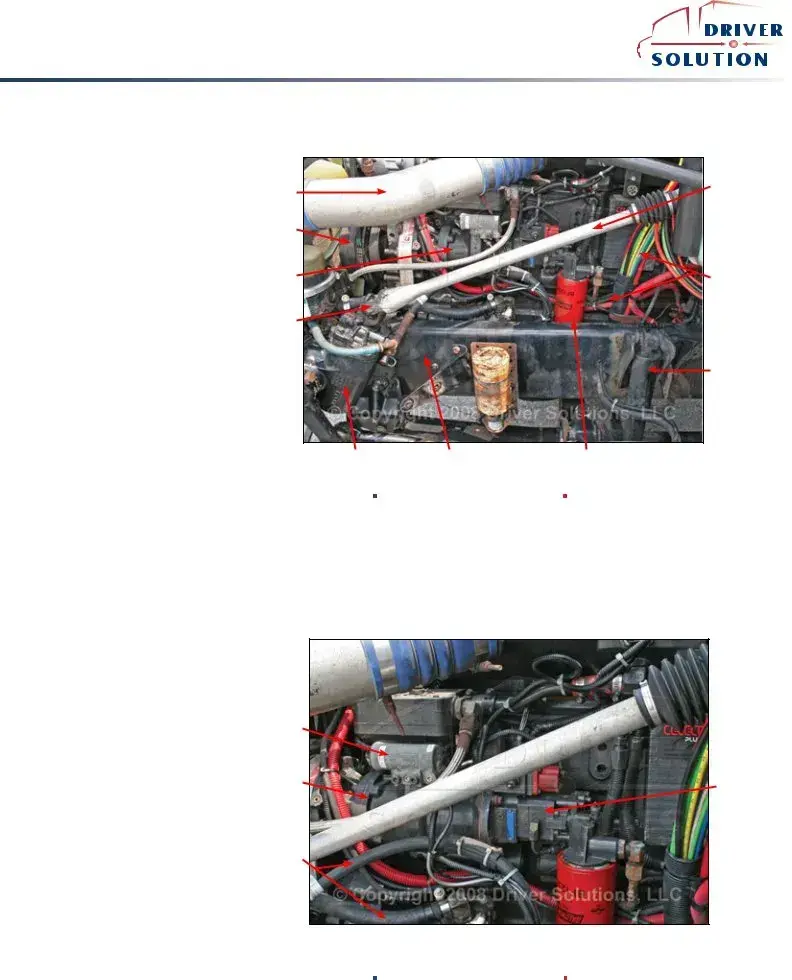

ENGINE COMPARTMENT - DRIVER SIDE CON’T |

||

|

|

|

|

o Mounted properly |

|

|

|

o Hoses attached and not leaking |

|

|

|

o Check for level and condition |

|

|

|

AIR COMPRESSOR |

|

|

|

o Mounted Securely |

Power Steering |

|

|

o No missing bolts or parts |

|

|

|

Reservoir |

|

|

|

o No air leaks at lines |

|

|

|

o Check if gear or belt driven |

|

|

|

o Belt no more than ¾ inch of play |

|

|

|

o Belts not cracked or frayed |

|

|

|

STEERING GEAR BOX |

Steering Gear |

|

|

Box |

|

|

|

o Mounted properly |

|

|

|

o No missing parts, nuts or bolts |

|

|

|

o Lines and hoses not leaking or |

Pitman Arm |

|

|

broken |

|

|

|

|

|

|

|

STEERING LINKAGE |

|

|

|

o Pitman arm, Drag link, Steering |

|

|

|

knuckle, Tie rods and tie rod ends |

|

|

|

o Not cracked, bent or broken |

Spring Mount |

Drag Link |

Leaf Spring |

o Castle nuts and cotter pins |

|

|

|

o Not missing and in place |

|

|

|

Reference Items |

Air Governor

Air Compressor

Engine Oil Pan

2

Class A CDL

®

®

AIR COMPRESSOR o Mounted Securely

o No missing bolts or parts o No air leaks at lines

o Check if gear or belt driven

o Belt no more than ¾ inch of play o Belts not cracked or frayed

STEERING GEAR BOX

o Mounted properly

oNo missing parts, nuts or bolts o Lines and hoses not leaking or broken

ENGINE COMPARTMENT - DRIVER SIDE CON’T

Engine Air Duct

Work

Fan Belts

Gear Driven Air

Compressor

Steering

Steering Column

Additional Hoses & Wiring

Shock Absorber

Steering Gear Box |

Frame Rail |

Fuel Filter |

Reference Items |

||

ENGINE COMPARTMENT - AIR COMPRESSOR

AIR COMPRESSOR o Mounted Securely

o No missing bolts or parts o No air leaks at lines

o Check if gear or belt driven

o Belt no more than ¾ inch of play o Belts not cracked or frayed

Air Governor

Gear Driven Air Compressor

Hoses

Fuel Pump

Reference Items |

3

Class A CDL

®

®

FRONT SUSPENSION

LEAF SPRINGS

o Not shifted or out of place

oNot cracked, broken or missing

SPRING MOUNTS

oMounted securely- front, back, and

oNot cracked or broken

SHOCK ABSORBER

oMounted Securely

oNot bent or dented o Not leaking

Shock Absorber

Leaf Spring

Tie Rod

Air Hose

Air LIne

Tie Rod End

Axle |

Service Brake |

Chamber |

Reference Items |

LEAF SPRINGS

o Not shifted or out of place

oNot cracked, broken or missing

SPRING MOUNTS

oMounted securely- front, back, and

oNot cracked or broken

SHOCK ABSORBER

oMounted Securely

oNot bent or dented o Not leaking

FRONT SUSPENSION CON’T

Frame Rail

Leaf Spring

Air Dryer location varies depending on model.

Located either behind the front bumper or behind the fuel tank.

Reference Items |

4

Spring Mount

Air Dryer

Class A CDL

®

®

HOSES AND LINES |

|

FRONT BRAKES |

|

|

|

||

o Mounted securely |

Service Brake |

|

|

o |

Not leaking |

|

|

o |

Not cracked or frayed |

Chamber |

|

|

Tire |

||

|

|

|

|

CHAMBER |

Push Rod |

|

|

o Mounted securely |

|

|

|

o Not dented or damaged |

|

Wheel |

|

o |

Not leaking |

|

|

SLACK ADJUSTER |

|

Slack Adjuster |

|

o |

No more than 1 inch of free play at |

Castle Nut |

|

the push rod with the brakes released. |

Cotter Pin |

Adjustment Nut |

|

o |

Not bent, broken, loose, or missing |

|

|

|

|

||

parts |

Steering |

|

|

|

|

Knuckle |

Brake Drum |

DRUMS |

|

||

|

|

||

o |

Not cracked, broken or dented |

|

|

o |

No oil leaking from inner oil seal, |

Snap Ring |

|

free of debris |

|

Brake Lining |

|

LININGS |

|

|

|

oNo cracked, broken or missing parts o Not less than ¼ inch in thickness

Reference Items |

HOSES AND LINES o Mounted securely o Not leaking

o Not cracked or frayed

CHAMBER

o Mounted securely

oNot dented or damaged

oNot leaking

SLACK ADJUSTER

oNo more than 1 inch of free play at the push rod with the brakes released.

oNot bent, broken, loose, or missing parts

DRUMS

oNot cracked, broken or dented

oNo oil leaking from inner oil seal, free of debris

LININGS

oNo cracked, broken or missing parts

oNot less than ¼ inch in thickness

FRONT BRAKES CON’T

Service Brake

Chamber

Push Rod

Clevis Pin &

Cotter Pin

Slack Adjuster

Reference Items |

Air Line

Air Hose

Shock Absorber

Spring

5

Class A CDL

®

®

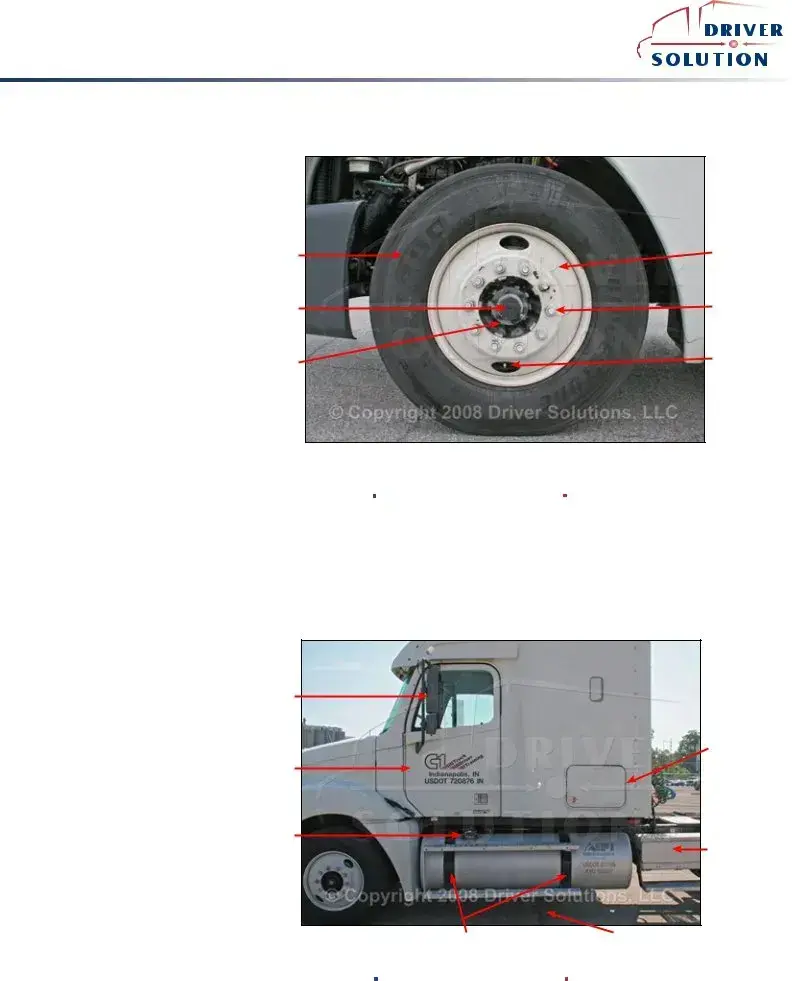

FRONT WHEEL

TIRES

oProper inflation – company or manufacturer specification

o No bulges, cuts, or retreads

o Minimum tread depth of 4/32”

RIMS

oNot bent, cracked, No welding repairs.

LUG NUTS

oNone are missing

oTight – no shinny threads, or rust trails

OUTER HUB OIL SEALS

oNot leaking, no missing bolts o Proper oil level

Tire |

Wheel |

|

Hub Oil |

Lug Nut |

|

Reservior |

||

|

||

Outer Hub |

Valve Cap |

|

Oil Seal |

|

Reference Items |

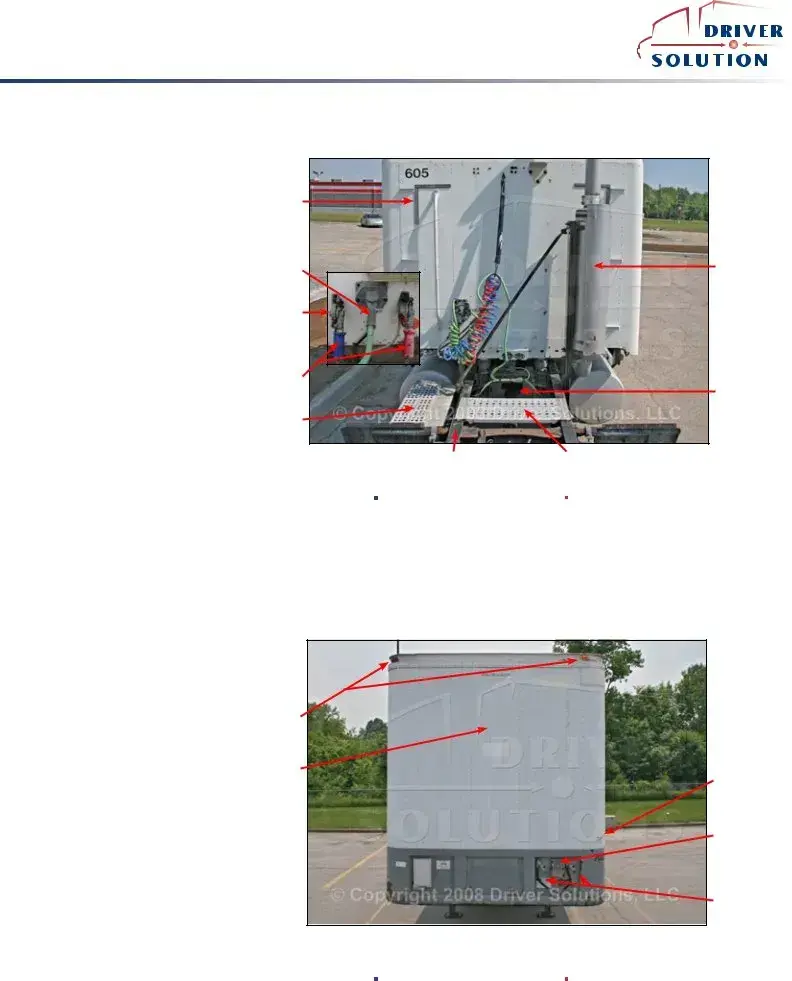

DRIVER FUEL AREA

DRIVER’S DOOR

oDoor opens and closes properly

oSeal is in good condition

DRIVER’S MIRRORS

oClean and free of obstruction

oNot cracked, broken, or damaged

oMounted securely

FUEL TANK

oMounted securely

o Not leaking

o Seal in cap OK

Mirror |

Storage |

Compartment |

Door |

Cap & Seal |

Battery Box & |

Cover |

Saddle Mounts |

Leaks |

Reference Items |

6

Class A CDL

®

®

AIR LINES & ELECTRIC LINE o Not cracked, frayed, cut, or kinked o Mounted securely at the glad hands o Not leaking

BEHIND THE CAB

BATTERY BOX & BATTERIES o Box is mounted properly

o Batteries are secure in the box o Lid secure

o Connections not corroded

CATWALK

o Mounted properly

oNot, missing, or damaged

oFree of obstructions

DRIVE SHAFT

oNot bent, or damaged

oCoupling,

EXHAUST SYSTEM

oSecurely mounted

oNot dented or damaged

oNot leaking

FRAME

oNot cracked, or damaged

oNo missing bolts

oNo illegal welds

LIGHTS & REFLECTORS

oClean and working

Lights & |

|

Reflectors |

|

Electrical Line |

Exhaust |

Glad Hand |

|

Service & |

|

Emergency |

|

Airlines |

Drive Shaft |

|

|

Battery Box & |

|

Batteries |

|

Frame |

Catwalk |

Reference Items |

FRONT OF TRAILER

HEADER BOARD

oNo holes or missing rivets

LIGHTS & REFLECTORS

oNone broken, cracked, or missing

oWorking and proper color of amber

Lights |

Header Board |

Height Sticker

Electric Hookup

Air Line

Reference Items |

7

Class A CDL

®

®

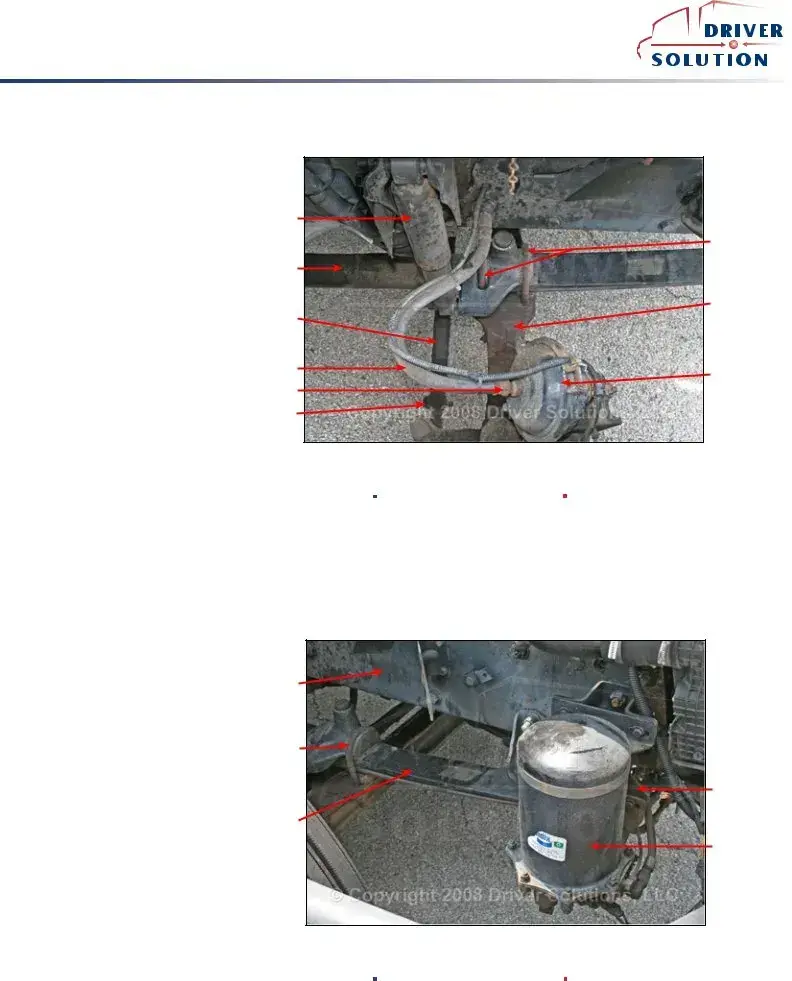

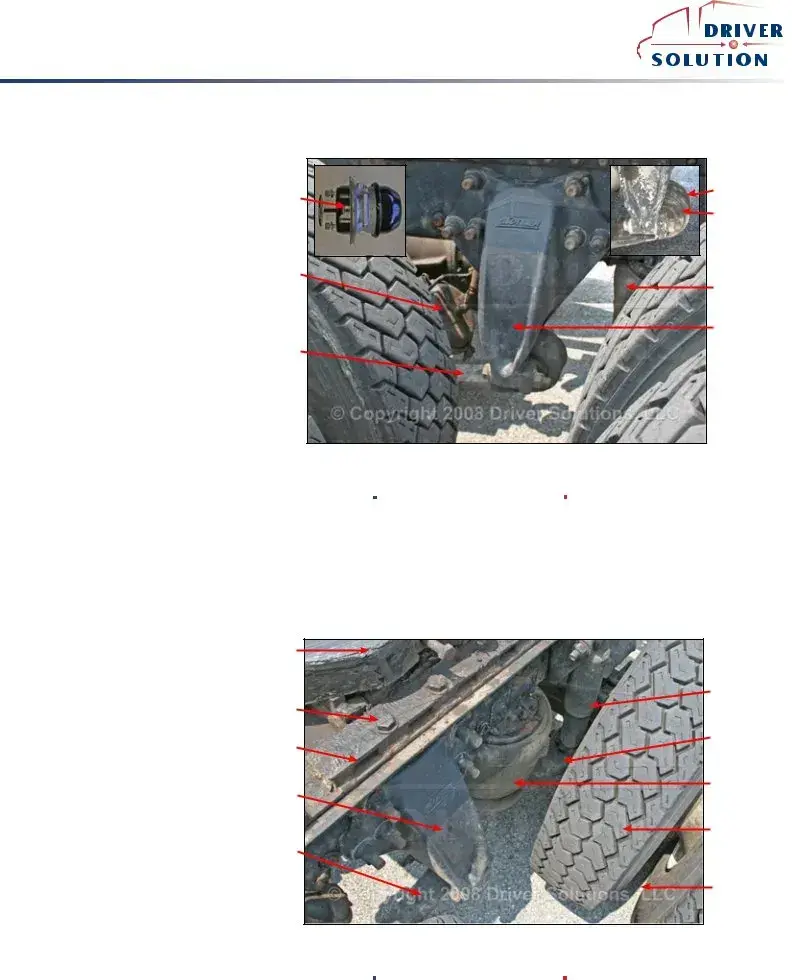

DRIVE AXLE SUSPENSION

CONTROL ARM MOUNT o Mounted securely

o Not bent, broken or damaged

CONTROLARM

oMounted securely – front, back, and

o Not cracked, or broken

SHOCK ABSORBER

o Mounted Securely

oNot bent, dented or leaking

TORSION BAR

oMounted Securely

oNot bent, broken or damaged

AIR BAGS

oMounted Securely

o Not leaking

Spring Brake |

Torsion Bar |

|

|

Chamber |

Control Arm |

|

|

Spring Brake |

|

Chamber |

Air Bag |

|

|

|

Control Arm |

|

Mount |

Control Arm |

|

Reference Items |

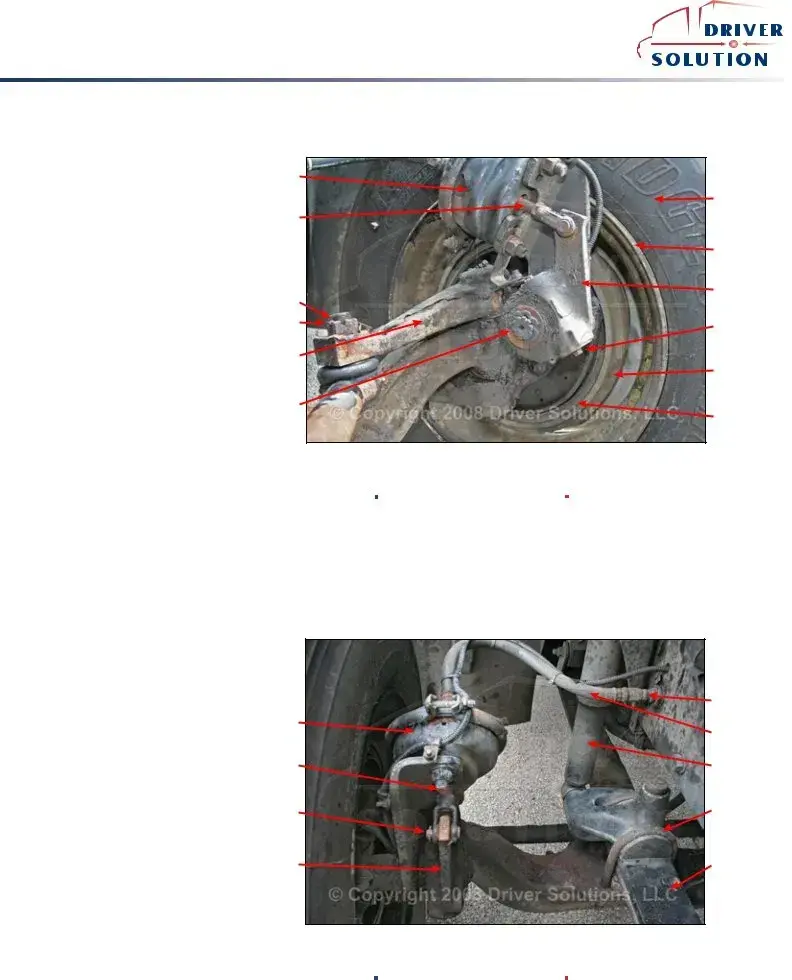

DRIVE AXLE SUSPENSION CON’T & FIFTH WHEEL

CONTROL ARM MOUNT o Mounted securely

o Not bent, broken or damaged

CONTROLARM

oMounted securely – front, back, and

o Not cracked, or broken

SHOCK ABSORBER

o Mounted Securely

oNot bent, dented or leaking

TORSION BAR

oMounted Securely

oNot bent, broken or damaged

AIR BAGS

oMounted Securely

o Not leaking

Skid Plate |

|

|

Shock Absorber |

Mounting |

|

Bolts |

|

Locking |

Spring |

|

|

Pins |

|

Control Arm |

Air Bag |

|

|

Mount |

|

|

Tire |

Control Arm |

|

|

Space |

Reference Items |

8

Class A CDL

®

®

HOSES AND LINES o Mounted securely o Not leaking

o Not cracked or frayed

CHAMBER

o Mounted securely

oNot dented or damaged

oNot leaking

SLACK ADJUSTER

oNo more than 1 inch of free play at the push rod with the brakes released.

oNo bent, broken, loose, or missing parts

DRUMS

oNot cracked, broken or dented

oNo oil leaking from inner oil seal, free of debris

LININGS

oNo cracked, broken or missing parts

oNot less than ¼ inch in thickness

DRIVE BRAKES & DRIVE SHAFT

Drive Shaft

Universal Joint

Differential

Reference Items |

Air Line

Service Brake Chamber

Frame

Brake Chamber Mount

Slack Adjuster

TIRES

oProper inflation - company or manufacturer specification.

o No bulges or cuts, can have retreads o Minimum tread depth of 2/32”

RIMS

oNot bent or cracked

oNo welding repairs

LUG NUTS

oNone missing

oTight – no shinny threads, or rust trails

OUTER AXLE SEAL

oNot leaking, no missing bolts

SPACE OR SPACER

oCheck for objects between wheels

oCheck for proper spacing

Lug Nuts

Outer Axle Seal

DRIVE WHEELS

Tire

Bud Rim

Dayton Rim |

Spacer |

Reference Items |

9

Class A CDL

®

®

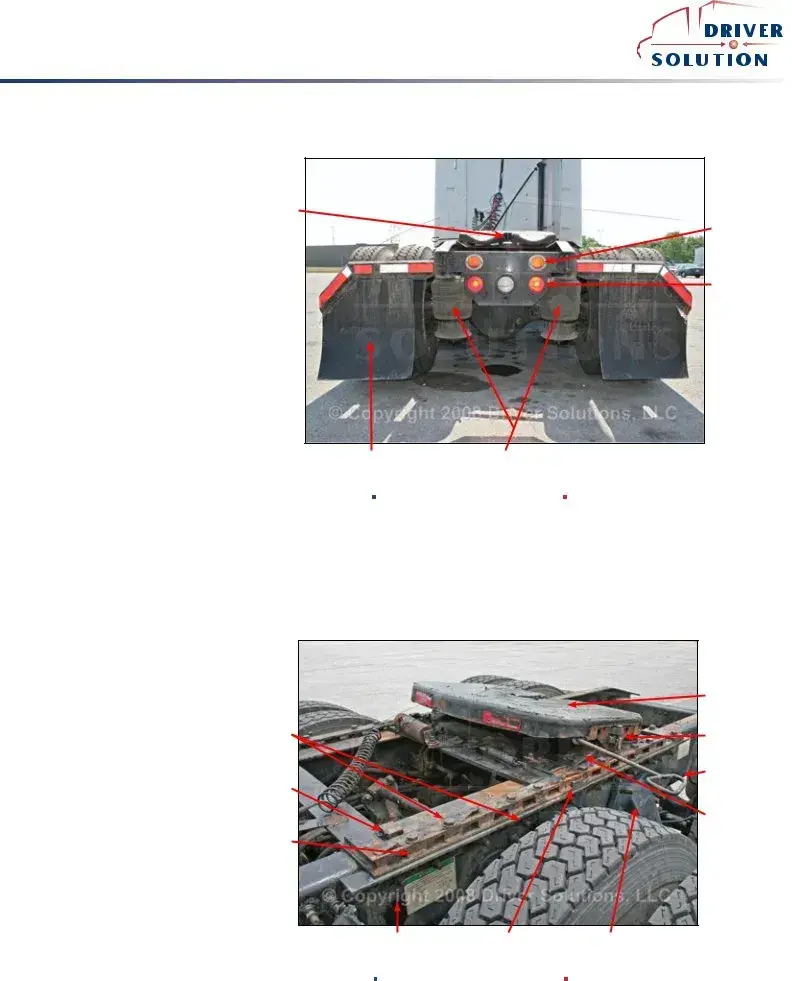

REAR OF TRACTOR

LIGHTS & REFLECTORS o Not cracked, or broken

o Working and proper color

SPLASH GUARDS

oNot missing or torn and properly mounted

Locking Jaws |

|

|

Reflectors |

|

Lights |

Splash Guard |

Air Bags |

Reference Items |

MOUNTING BOLTS

oNone missing or broken

RELEASE ARM

oNot bent, broken, or damaged

oEngaged in the lock position

LOCKING PINS

oNo missing or broken parts

oEngaged and locked

PLATFORM

oSecurely holds skid plate

oNot cracked, or broken

SKID PLATE

oMounted properly on the platform

oProperly greased

oTilting freely

Mounting Bolts

Slide Stops (all 4 corners)

COUPLING SYSTEM

Skid Plate |

Pivot Pin |

Release Arm |

Platform |

KING PIN |

Welds |

oNot broken, bent, or damaged

APRON

oNo bends or damage to visible portions

GAP

oCheck that the trailer apron is lying flat on the fifth wheel skid plate

Frame |

Slide Locking Pin |

Spring Mount |

JAWS |

Reference Items |

|

|

|

|

o Check that the locking jaws are fully |

|

|

closed around the shank of the king pin |

10 |

|

Frequently Asked Questions

-

What is a Pre Trip Inspection Checklist?

The Pre Trip Inspection Checklist is a vital document used by drivers to ensure that their vehicle is safe and roadworthy before embarking on a trip. This checklist includes various components that need to be inspected, such as brakes, lights, tires, and fluid levels. Conducting this inspection helps prevent accidents and mechanical failures during travel.

-

Why is it important to complete a Pre Trip Inspection?

Completing a Pre Trip Inspection is crucial for the safety of the driver, passengers, and other road users. By identifying potential issues before hitting the road, drivers can address problems that could lead to breakdowns or accidents. This proactive approach not only enhances safety but also ensures compliance with transportation regulations.

-

How often should I perform a Pre Trip Inspection?

A Pre Trip Inspection should be performed every time you operate a vehicle, especially for commercial drivers. This means that before each trip, you should take the time to go through the checklist thoroughly. Consistency in this practice helps maintain vehicle safety and reliability over time.

-

What should I do if I find a problem during the inspection?

If you discover a problem during your Pre Trip Inspection, it is essential to address it immediately. Depending on the severity of the issue, you may need to repair it yourself or seek professional assistance. Do not proceed with your trip until all identified issues are resolved, as this could compromise safety.

-

Can I customize the Pre Trip Inspection Checklist?

Yes, you can customize the Pre Trip Inspection Checklist to fit your specific vehicle type and personal needs. While there are standard components that should be included, adding items relevant to your vehicle or industry can enhance the thoroughness of your inspection. Ensure that any modifications still cover all critical safety aspects.

Misconceptions

Understanding the Pre Trip Inspection Checklist is crucial for ensuring safety on the road. However, several misconceptions often arise regarding its purpose and use. Here are seven common misunderstandings:

-

It’s only for commercial drivers.

This checklist is beneficial for all drivers, not just those operating commercial vehicles. Personal vehicle owners can also use it to enhance safety.

-

It’s a one-time requirement.

Some believe that once a vehicle passes inspection, it doesn't need to be checked again. In reality, regular inspections are essential for ongoing safety.

-

It’s just a formality.

Many view the checklist as a mere formality. However, it serves a vital role in identifying potential issues before they become serious problems.

-

Only mechanics can conduct inspections.

While mechanics are trained professionals, any driver can perform a basic pre-trip inspection using the checklist. It encourages personal responsibility for vehicle safety.

-

It covers only the exterior of the vehicle.

Some people think the checklist focuses solely on the outside. In truth, it includes checks for interior components and systems as well.

-

It’s not legally required.

Many drivers are unaware that certain jurisdictions require a pre-trip inspection for commercial vehicles. Compliance is not just a best practice; it can be a legal obligation.

-

It takes too much time.

While it may seem time-consuming, a thorough pre-trip inspection can actually save time and money by preventing breakdowns and accidents.

By dispelling these misconceptions, drivers can better appreciate the importance of the Pre Trip Inspection Checklist and its role in promoting road safety.

Common mistakes

-

Skipping Sections: Many individuals overlook entire sections of the checklist. Each part is important for ensuring vehicle safety.

-

Inaccurate Measurements: Some people fail to take accurate measurements, such as tire pressure or fluid levels. This can lead to safety issues on the road.

-

Rushing Through the Process: Completing the checklist too quickly can result in missed items. Taking time to inspect thoroughly is crucial.

-

Not Documenting Issues: If an issue is found, failing to document it properly can lead to problems later. Always note down any concerns for follow-up.

-

Ignoring Warning Lights: Some drivers disregard warning lights on the dashboard. These indicators can signal serious mechanical issues that need immediate attention.

-

Neglecting the Interior: People often focus only on the exterior and mechanical parts, ignoring the interior. Checking seat belts, mirrors, and controls is equally important.

-

Using Outdated Checklists: Utilizing an old version of the checklist can lead to missing new safety requirements or procedures. Always ensure you have the latest version.

-

Failing to Get a Second Opinion: Some individuals do not seek a second set of eyes. Having another person review the checklist can catch mistakes that one might miss.

-

Not Following Up on Repairs: After noting issues, neglecting to follow up on repairs can lead to unsafe driving conditions. Ensure all noted problems are addressed before hitting the road.

Additional PDF Templates

Cheaper Insurance Than Progressive - Each completed form should embody professionalism and attention to detail from the repair shop.

The New York Motorcycle Bill of Sale form is an important document used to record the sale and transfer of ownership of a motorcycle. It serves as proof of purchase for both the buyer and the seller. Having this form completed accurately can help prevent disputes and ensure a smooth transaction. For more information and to access the form, you can visit documentonline.org/blank-new-york-motorcycle-bill-of-sale.

Money Receipt Sample - Optimize your cash flow management with this form.

What Does a Esa Letter Look Like - Emotional Support Animals do not require specialized training to assist their owners.

Document Data

| Fact Name | Description |

|---|---|

| Purpose | The Pre Trip Inspection Checklist is designed to ensure that vehicles are safe and roadworthy before they begin a trip. |

| Components | This checklist typically includes items such as brakes, lights, tires, and fluid levels to be inspected prior to departure. |

| Regulatory Requirement | In many states, completing a Pre Trip Inspection is mandated by federal and state regulations, including the Federal Motor Carrier Safety Administration (FMCSA) guidelines. |

| Documentation | Drivers must maintain a record of completed inspections, which can be requested during audits or inspections by regulatory authorities. |

| Frequency | The checklist should be completed before every trip, ensuring ongoing compliance with safety standards. |

Similar forms

The Vehicle Maintenance Log serves as a record of all maintenance activities performed on a vehicle. Similar to the Pre Trip Inspection Checklist, it is designed to ensure that the vehicle remains in good working condition. Both documents require detailed entries regarding inspections, repairs, and any issues identified. The Vehicle Maintenance Log provides a historical account that can help identify recurring problems, just as the Pre Trip Inspection Checklist identifies potential issues before a trip begins.

The Daily Inspection Report is another document that shares similarities with the Pre Trip Inspection Checklist. This report is typically used by drivers to record the condition of a vehicle at the start of each day. Both documents focus on safety and operational readiness. The Daily Inspection Report may include checks for lights, brakes, and tires, paralleling the Pre Trip Inspection Checklist's emphasis on thorough vehicle evaluation before use.

The Safety Inspection Form is designed to assess compliance with safety regulations and standards. Like the Pre Trip Inspection Checklist, it aims to identify safety-related issues. Both documents require a systematic approach to ensure that all necessary components are evaluated. The Safety Inspection Form may be used periodically, while the Pre Trip Inspection Checklist is used specifically before each trip, but both share the goal of maintaining safety on the road.

Understanding the importance of properly structured agreements is essential for both landlords and tenants in real estate transactions. One such vital document is the Residential Lease Agreement, which clearly outlines the terms of rental, ensuring that both parties are aware of their expectations and responsibilities. For more information on how to create these agreements and what elements to include, you can visit OnlineLawDocs.com.

The Maintenance Request Form is another document that complements the Pre Trip Inspection Checklist. When a driver identifies a problem during a pre-trip inspection, they may use this form to request necessary repairs. Both documents serve to enhance vehicle safety and functionality. The Maintenance Request Form captures specific issues noted in the Pre Trip Inspection Checklist, ensuring that any concerns are formally documented and addressed in a timely manner.

The Incident Report Form is similar in that it documents events related to vehicle operation, particularly accidents or breakdowns. While the Pre Trip Inspection Checklist is proactive, focusing on prevention, the Incident Report Form is reactive, detailing what occurred after an issue arises. Both documents are essential for maintaining safety and accountability, providing a clear record of vehicle conditions and incidents.

Lastly, the Driver's Log is a record that tracks a driver’s hours of service and vehicle usage. This document is similar to the Pre Trip Inspection Checklist in that it promotes safety and compliance with regulations. While the Pre Trip Inspection Checklist focuses on the vehicle's condition, the Driver's Log ensures that drivers adhere to legal requirements regarding driving limits and rest periods, both contributing to overall road safety.